AUTOMOTIVE ADHESIVES & SEALANTS

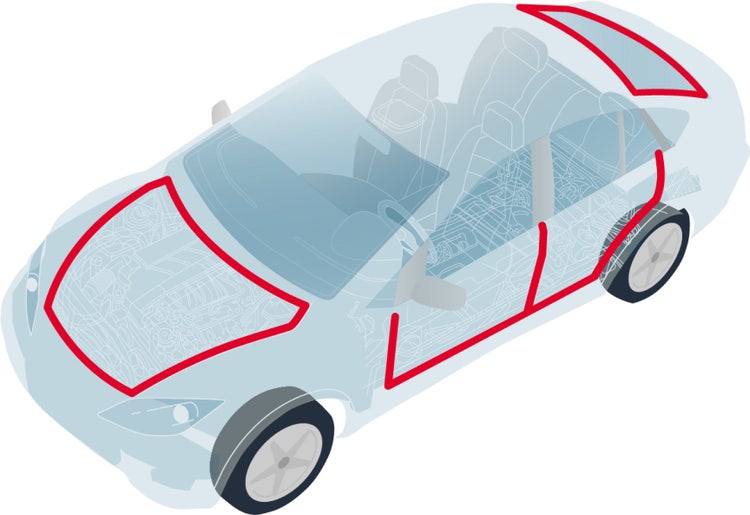

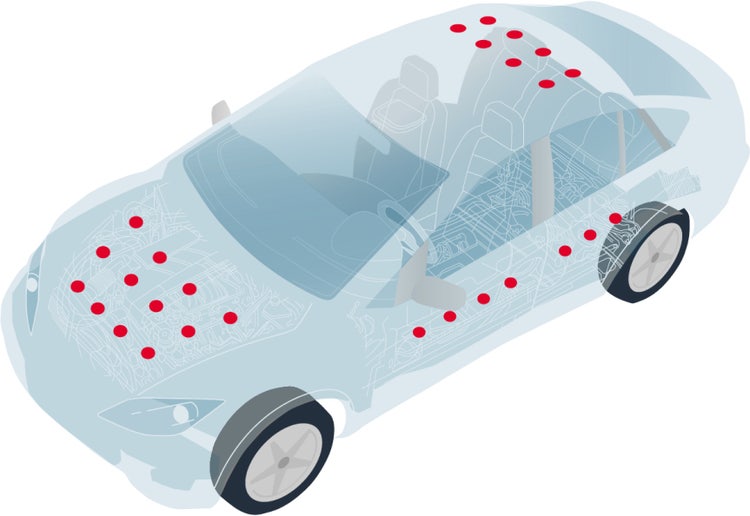

Weld Shop

- Weld Bond Adhesives

- Hem Flange Adhesives

- Mastic Adhesive

- Pumpable Sheet Metal Stiffener (PSS)

- Pumpable Sound Deadener (PSD)

- Spot Sealer

Weld Shop Engineered Products

Sunstar leads the way with a comprehensive line of high‐performance adhesives, sealers, stiffeners and sound deadening products developed for the automotive manufacturer’s weld shop. Trusted by manufacturers around the world, Sunstar’s weld shop products offer outstanding adhesion, anti‐corrosive properties, and workability. Our formulations can be customized to your manufacturing needs. Contact us to discuss your specifications.

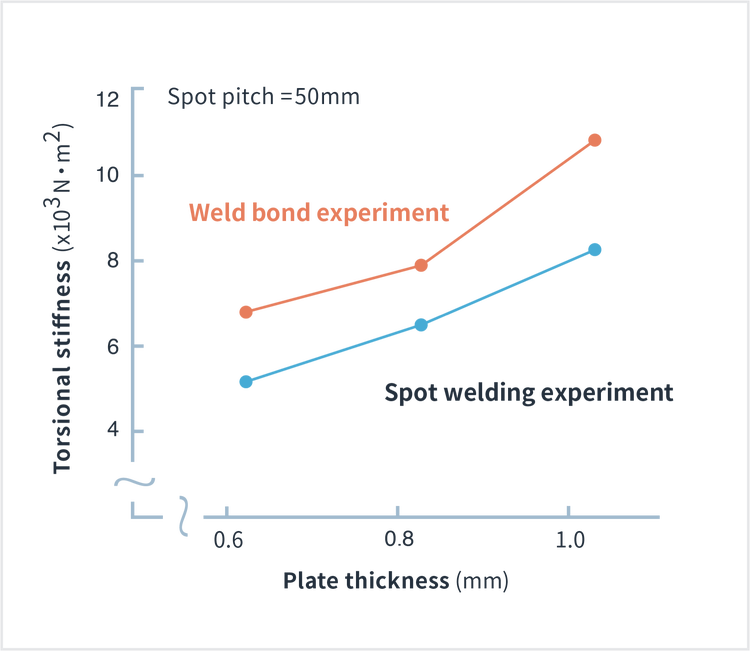

Weld Bond Adhesive

Our advanced weld bond adhesives are a one‐component thermal cure epoxy adhesives that improve stiffness and fatigue properties within the body structure. They are ideal for spot welding applications to prevent stress concentration and to reduce degradation due to fatigue from vibration.

Distinct Benefits

- Excellent adhesion to oily steel plates. Bond components directly to oily steel plates since no treatment to the metal is required before application.

- Contributes to light‐weight vehicles. Using a weld bond method, manufacturers can reduce steel thickness to minimize vehicle weight without compromising body rigidity.

- Reduces volume of welding points. Weld bond adhesive improves panel stiffness, thereby reducing the number of weld points required, compared to panels where weld bond adhesive has not been applied.

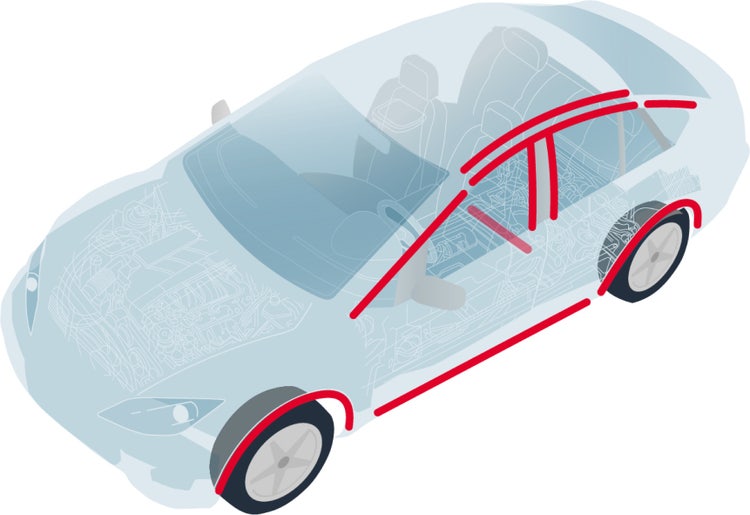

- Exceptional line compatibility. Throughout the entire line—from pre‐treatment through electrodeposition coating—weld bond adhesive maintains its integrity with no deformation or outflow, even in running water or shower.

Production process

Applicable substrates

✓ Full adhesion / – Not recommended

*1 Depends on product

Curing method

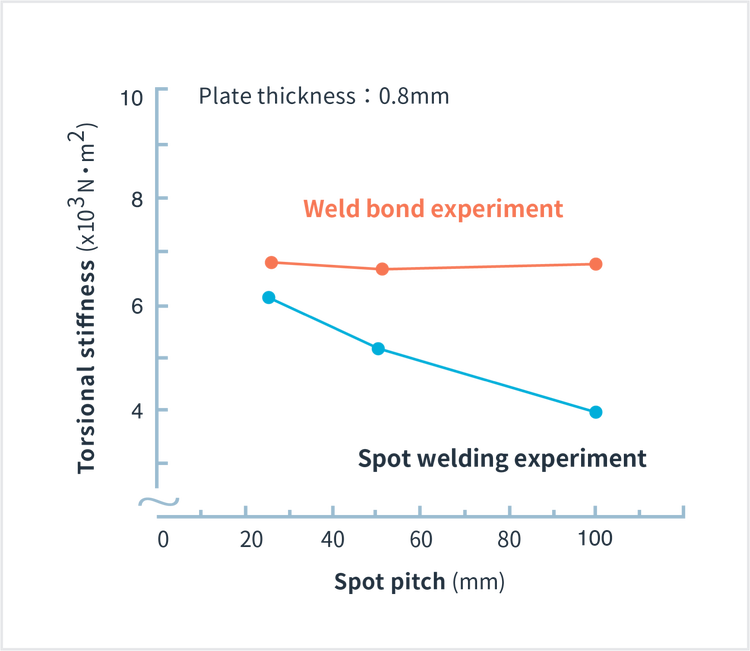

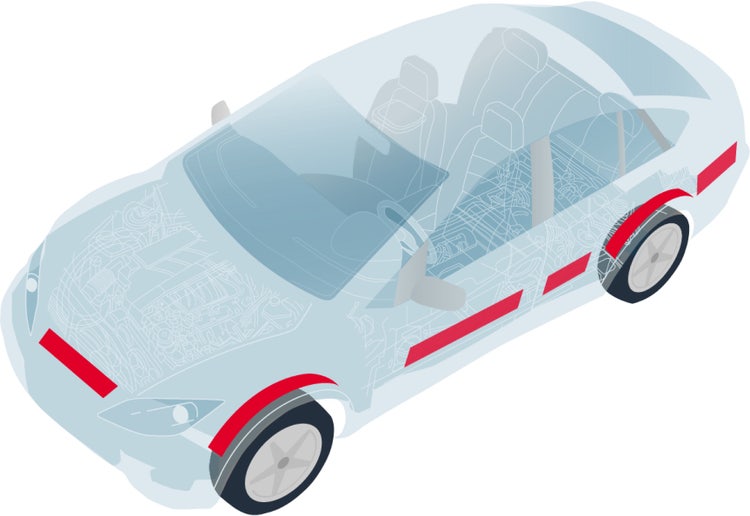

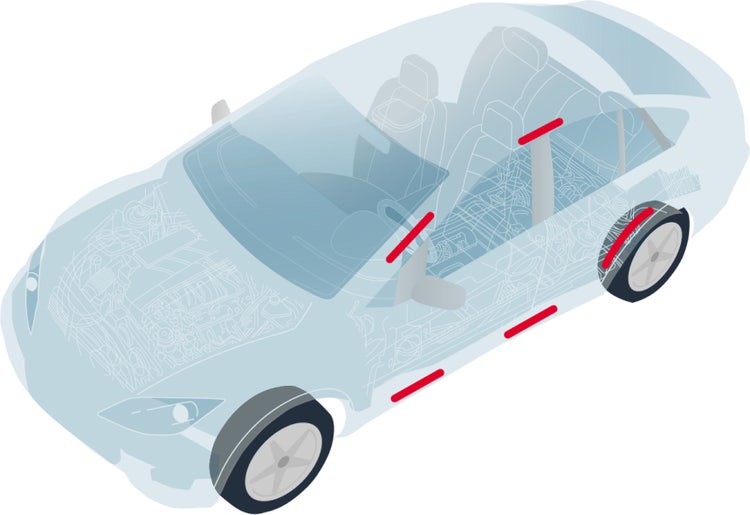

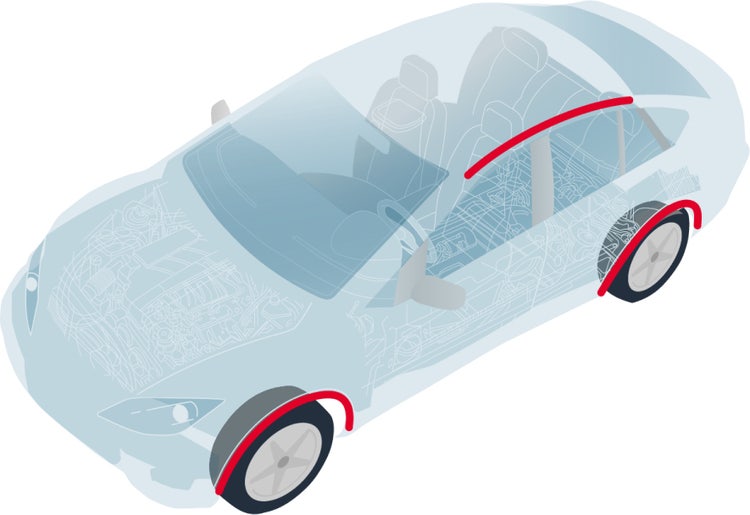

Application parts

Hem Flange Adhesive

Designed for hem flange applications commonly found on doors, hoods and trunk lids, these one‐component, thermal‐cure epoxy‐based adhesives are a high‐performance, cost‐effective alternative to welding. Sunstar’s hem flange adhesives are engineered to bond a variety of sheet metal components, including aluminum, providing increased stiffness and enhanced corrosion protection of the hem flange.

Distinct Benefits

- Firm adhesion to oily steel plates. Hem flange adhesive can be applied to oily steel plates directly and without the need for pre‐treatment of the metal.

- Flexible application. Hem flange adhesive can be applied robotically and is suitable for the shot application method.

- Panel movement prevention function. Our adhesives that feature a glass bead‐filled design create a bond‐line spacer and high strength bond. Panels can be fixed temporarily in place, and then mechanically “locked” into position when compacted with a hem press. Multiple bead diameters are available to suit specific manufacturing process requirements.

- Tailored to your needs. Using the base formulation as a starting point, the Sunstar R&D team can modify the performance characteristics based on your needs. Contact us to discuss your specifications, and we’ll engineer the optimum solution.

Production process

Applicable substrates

✓ Full adhesion / – Not recommended

*1 Depends on product

Curing method

Application parts

Mastic Adhesive

Sunstar’s mastic adhesive was developed specifically to bond exterior automotive panels to the vehicle’s inner panel structure, such as on roofs, doors, and hoods. This one‐component synthetic rubber sealer remains elastic after curing to reduce panel flapping and to prevent panel distortion

Distinct Benefits

- Great application flexibility. With minimal stringing effect, our mastic adhesive provides controlled application for consistent performance during robotic application. The easy‐ to‐handle formula can also be applied with a handgun or pump.

- Excellent adhesion to oily steel plates. Mastic adhesive can be applied directly to oily steel plates without pre‐treating the metal, creating a strong and permanent bond.

- Ideal for aluminum panel bonding. Our mastic adhesive is suitable for a variety of metals and is an excellent choice for assemblies where aluminum and other alloys are used.

- A formulation for virtually every need. Mastic adhesive is available in a range of hardness and foam expansion ratios to provide optimal performance for each application. Contact us to discuss your needs and we’ll engineer the optimum solution.

Production process

Applicable substrates

✓ Full adhesion / – Not recommended

*1 Depends on product

Curing method

Application parts

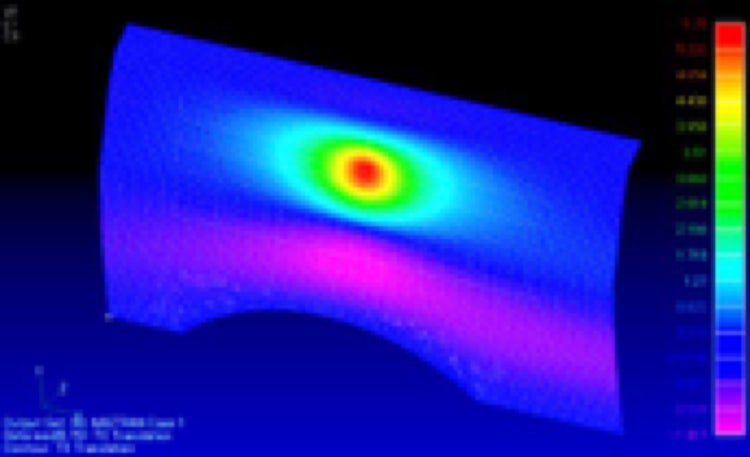

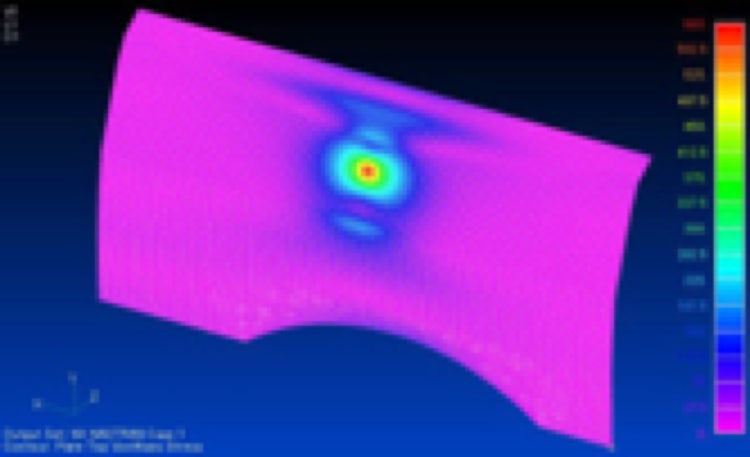

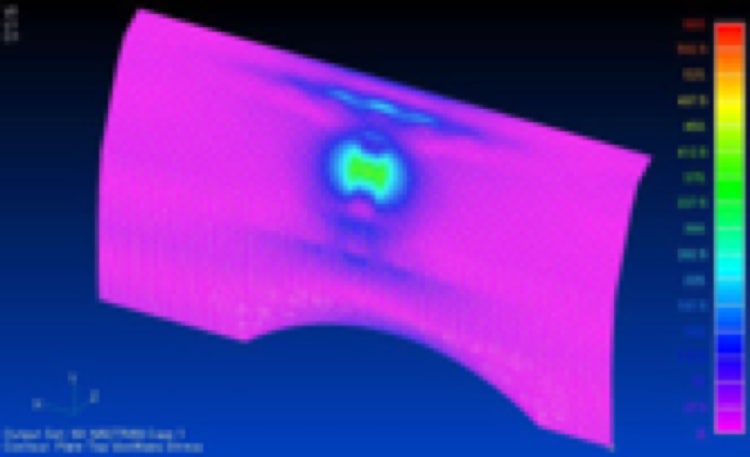

Pumpable Sheet Metal Stiffener (PSS)

Thinner automobile panels help reduce vehicle weight, but are prone to flutter and excessive in‐cabin noise due to aerodynamic effects at highway speed. Sunstar’s Pumpable Sheet Metal Stiffener (PSS) reinforces those thin outer panels, increasing panel rigidity and minimizing sound.

Distinct Benefits

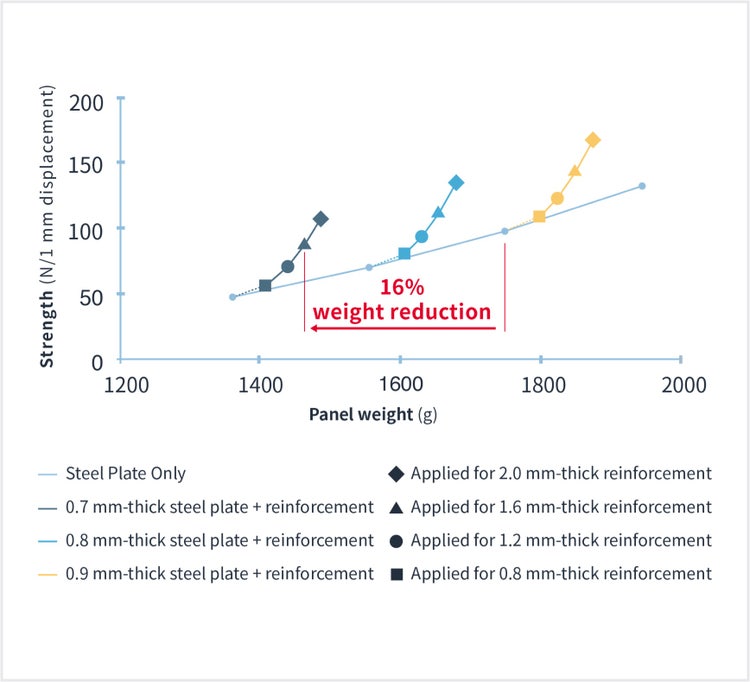

- Thick panel performance from a thinner panel. A 0.7 mm‐thick steel plate with a sheet metal reinforcement is equivalent to the strength of a 0.9 mm‐thick steel. This equates to a 16% weight reduction while reducing stress at the pressurized part.

- Automated application cuts labor time and cost. Robotic application of PSS saves labor that would otherwise be required for bonding molded reinforced adhesive sheets.

- Reduces waste and lessens environmental impact. Since a metered amount of PSS can be applied to select targeted locations, material consumption and weight are significantly reduced, creating a more environmentally‐conscious solution. There is no scrap material as found with reinforced adhesive sheets, including wasteful release paper.

- High application flexibility. PSS is an amorphous paste material that provides a wide range of application options. It can be applied to a specific location or across an entire panel, providing just the right amount of reinforcement needed. Part design alterations due to vehicle model changes are just a matter of teaching the updated application to the robots.

Production process

Applicable substrates

✓ Full adhesion / – Not recommended

Curing method

Application parts

Pumpable Sound Deadener (PSD)

Pumpable Sound Deadener (PSD) is a high‐expansion foam that readily fills voids. Designed specifically to reduce noise inside the automotive cabin, PSD is the ideal solution to fill gaps and channels within the auto body that are vulnerable to wind, thereby blocking the flow of air that can generate unpleasant noise at driving speeds.

Distinct Benefits

- Ease of application. PSD is designed to be robotically applied, making it easy and efficient to fill gaps and channels.

- Excellent adhesion to oily surfaces. PSD shows excellent adhesion to oily surfaces, assuring a strong hold, a gap‐free fill of open space, and maximum noise reduction.

- High foam expansion ratio. With a high‐performance expansion formula, PSD foams aggressively, even in low‐temperature baking applications.

Production process

Applicable substrates

✓ Full adhesion / – Not recommended

Curing method

Application parts

Spot Sealer

Sunstar Spot Sealer is engineered to effectively seal vulnerable gaps along spot‐welded seams on automotive bodies where traditional body sealers cannot be applied. Spot Sealer is applied as a thin coat that then foams during thermal curing to fill gaps.

Distinct Benefits

- Protects and Seals. Spot Sealer creates a rustproof, waterproof and dustproof seal that protects spot‐welded metal parts.

- Preserves weld integrity. In addition to keeping corrosive elements out, the chemistry of Spot Sealer never compromises the strength of welds

- Demonstrates excellent shower resistance.

- Provides excellent workability. Using robotic application, there is minimal stringing effect, resulting in consistent application. Plus, Spot Sealer requires no pre‐treatment of metal – it adheres directly to oily steel panels.

- Can be used as a mastic sealer. Spot Sealer can also be used in place of mastic adhesives, which can simplify the application process and product inventory management.

Production process

Applicable substrates

✓ Full adhesion / – Not recommended

Curing method

Application parts

We’re ready to help

Contact us to find out how our advanced engineering solutions can help your business

Trusted by the world’s leading companies to solve unique engineering challenges

Your innovation partner

Chosen by the best