AUTOMOTIVE ADHESIVES & SEALANTS

Assembly Shop

- Direct Glazing Adhesive

- Heat‐curing Elastic Adhesive

- Interior Adhesive

Assembly Shop Engineered Products

Our assembly line adhesives deliver proven performance for applications where automotive components are bonded during assembly. From glass installation to interior assemblies, Sunstar has the engineered adhesive products that are trusted by manufacturers worldwide.

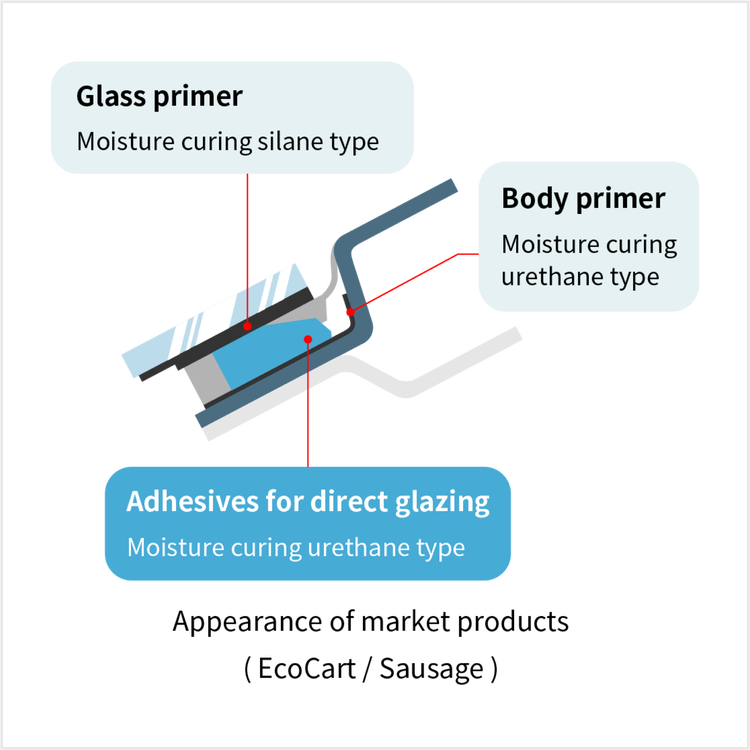

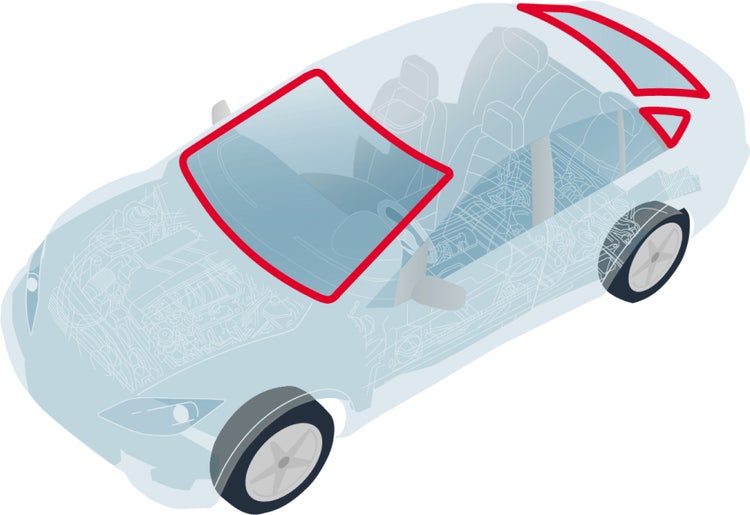

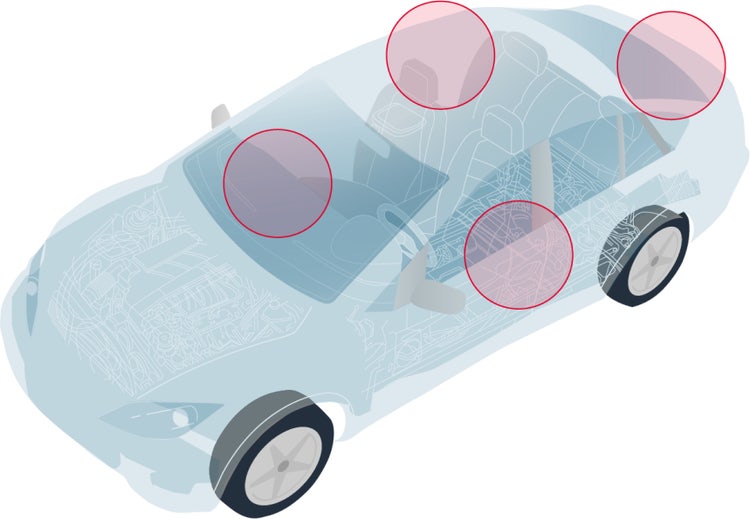

Direct Glazing Adhesive

Sunstar was the first commercial producer of direct glazing for glass bonding, and continues to lead the industry. Direct glazing creates a strong, yet flexible bond for critical applications where glass is joined to painted body panels such as windshield installations. Our Direct Glaze uses a polyurethane technology and is the product of choice on more than 60% of Asia’s automotive assembly lines.

Distinct Benefits

- Superior bonding performance. Our Direct Glazing Adhesive cures to a strong, rubber‐ like consistency for exceptional sealing performance.

- Increased vehicle safety. Direct Glazing securely bonds glass and body panels together to assure a strong, reliable fit while contributing to greater structural rigidity.

- Healthier work and driving environments. Developed with an organic, solvent‐free formula, our Direct Glazing Adhesives reduces VOC emissions in the working environment and within the automotive cabin.

A Full Range of Direct Glazing Adhesive Solutions

Primerless Direct Glazing Adhesives:

In addition to providing reliable adhesion strength and durability, these adhesives reduce environmental impact and support worker health.

- Promotes shorter manufacturing time since there is no need to wait for workability of primer

- Cuts costs by eliminating need for primer

High‐viscosity Direct Glazing Adhesives:

These adhesives produce a strong bond for applications where little or no temporary fixing of parts is required.

- High‐viscosity formulation provides excellent holding properties for glass positioning without the need for positioning pins

- Has exceptional initial strength—stronger than standard Direct Glazing adhesives

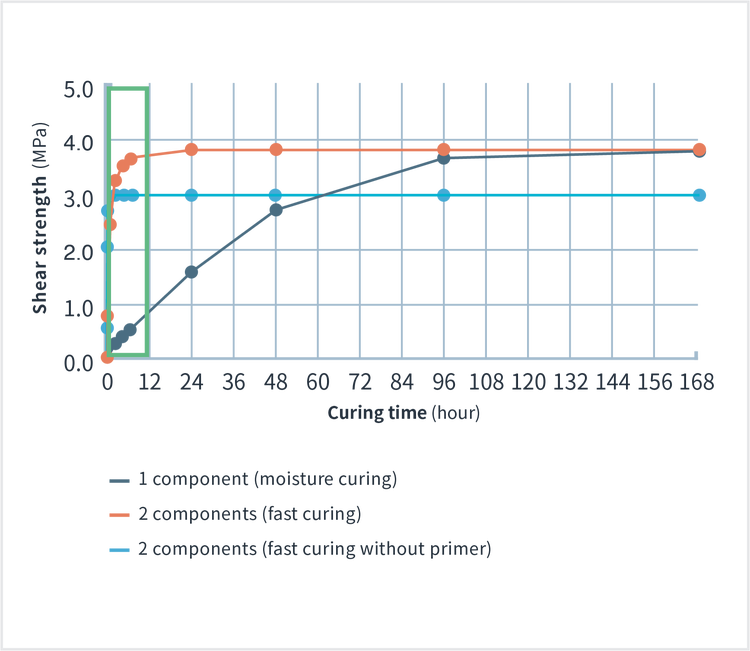

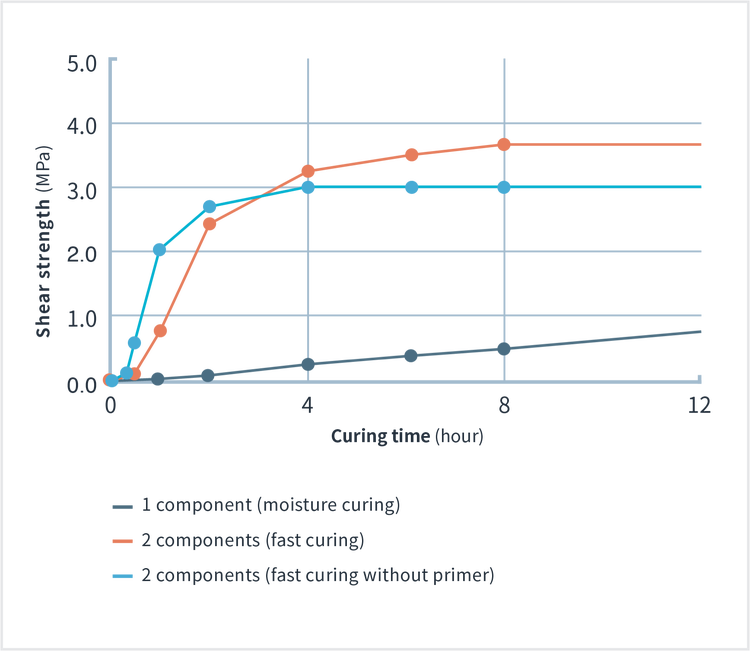

Two‐component Direct Glazing Adhesives:

Our fast‐curing formulation provides both initial workability and fast curing performance. Parts can be temporarily fixed and repositioned, then the adhesive cures quickly, cutting wait time on the line.

- Activated by mixing base agent and curing agent just prior to use with a static mixer

- Cures faster than one‐part adhesives, even at room temperature

- Promotes greater efficiency on the manufacturing line

Direct Glazing Adhesives for Aftermarket Repair Work

From general‐purpose to fast‐curing to high‐viscosity adhesives, Sunstar has the bonding needs of the aftermarket repair industry covered.

- Proven adhesion and sealing performance. Sunstar adhesives are the choice of OEM manufacturers

- No toxic organic solvents. Our adhesives contain no noxious chemicals, including harmful BTX.

- Environmentally‐friendly EcoCart and Sausage spec products. Packaging is designed to reduce waste volume and the associated costs, creating a more efficient and responsible solution.

Production process

Applicable substrates

✓ Full adhesion / – Not recommended

*2 Depends on materials and primer/primerless

*3 Primer required

Curing method

Application parts

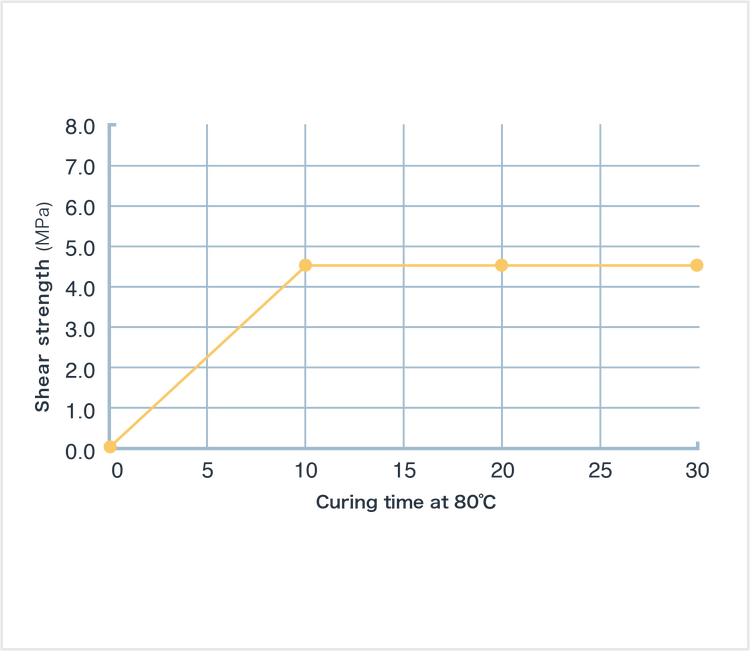

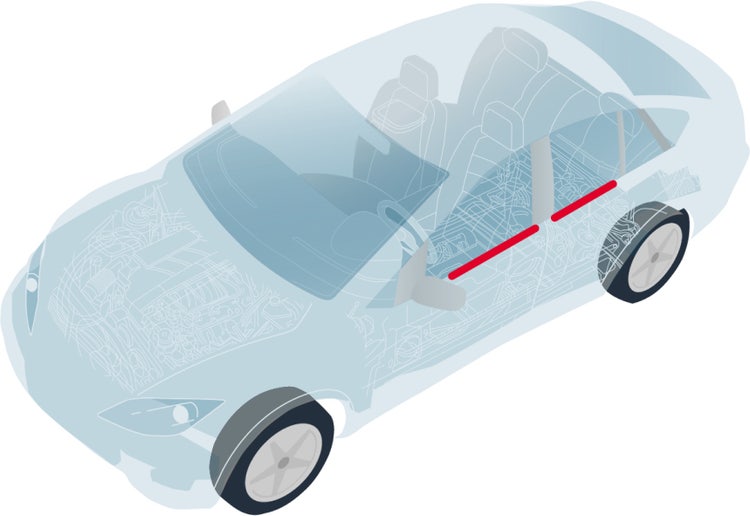

Heat‐Curing Elastic Adhesive

Sunstar offers one‐component, heat‐curing urethane‐type adhesives that enable glass to be bonded at lower temperatures and in less time than traditional methods.

Distinct Benefits:

- Cures in 10‐minutes. Rapid curing at just 80° Celsius saves production time and energy over traditional methods.

- Strong elasticity and adhesion in just three minutes. Bond can be accelerated by increasing heat from 80° Celsius to 120° Celsius* for three minutes or longer**

- Reduces parts processing time. Faster curing means bonded components are ready for installation sooner.

- Eliminates holding time. Rapid curing properties virtually eliminate the need to place components in a holding area for a prolonged curing period.

- Keeps product inventory manageable. Oven heating accelerates curing, which keeps the line moving and the work‐in‐process inventory to a minimum.

* Materials temperature.

** Holding period

Production process

Applicable substrates

✓ Full adhesion / – Not recommended

*2 Primer or surface treatment required

*3 GF contained

*4 Cleaner Required

Curing method

Application parts

Interior Adhesives

Sunstar has a full range of specialty interior adhesives to meet virtually every interior assembly need, including adhesives specially formulated for hard‐to‐bond untreated polypropylene components.

Our product lineup includes:

- Two‐component polyurethane adhesives

- Moisture‐curing, one‐part polychloroprene adhesives

- Water‐soluble adhesives

- Specialty adhesive for polypropylene (PP)

- Moisture‐curing, one‐part Low‐VOC adhesives

- Pre‐coating adhesives

- Hot‐melt adhesives

Distinct Benefits of our Interior Adhesives Products:

- Ideal for flexible and soft materials. Easily and securely bond PP, PE and urethane foam to diverse base materials, including untreated polypropylene, ABS, and PC/ABS.

- Compatible with all molding and application types. Our Interior Adhesives provide exceptional performance for vacuum forming, press fit, crimp fit, and pre‐apply spray / roll coating.

- Solvent and waterborne formulations. Sunstar has a range of adhesive options to meet performance, efficiency and environmental needs of the industry. Let us help you find the best solution for your need.

Production process

Adhesive property

✓Full adhesion / – Not recommended

Curing method

Application parts

We’re ready to help

Contact us to find out how our advanced engineering solutions can help your business

Trusted by the world’s leading companies to solve unique engineering challenges

Your innovation partner

chosen by the best